Thread rolling flat Dies

Flat dies system has two die flats, the bottom one is held stationary and the other slides. The blank is placed of one end of the stationary died then the moving die slides over the blank, which causes the blank to roll off the stationary lower die in a finished form. Flat dies are available in various thread forms such as ANSI, BS, DIN and JIS amongst other. It can be offered with or without holding angles. Flat dies produce external threads by the process of cold forming, sutilize one stationary and one moving die to form the threads.

Features

- Quick and accurate die set up with long life

- Precise control of die dimensions

- High precision, stability and high durability

- Stronger threads and better fatigue resistance due to work hardening

Application

For mass production of the thread objects or tapping, such as bolts and screws.

Normally, there are 2 piece of flat dies in a set, even though production speed is lower than planetary dies but so do the cost .

Generally, applying to mass production to reduce the cost .

Select material HSS or Nitride surface treatment can well-enhance the durability of dies to reduce the cost .

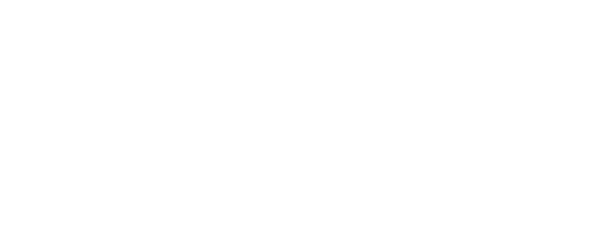

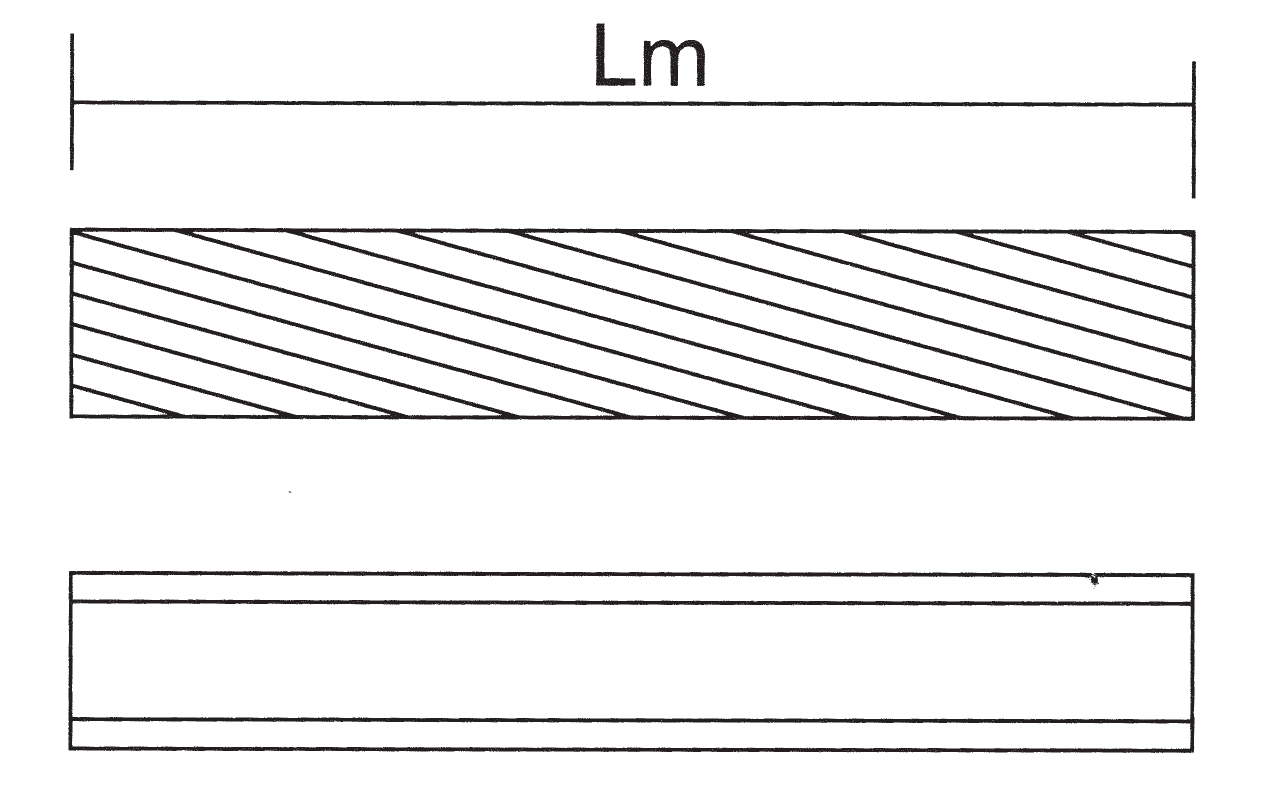

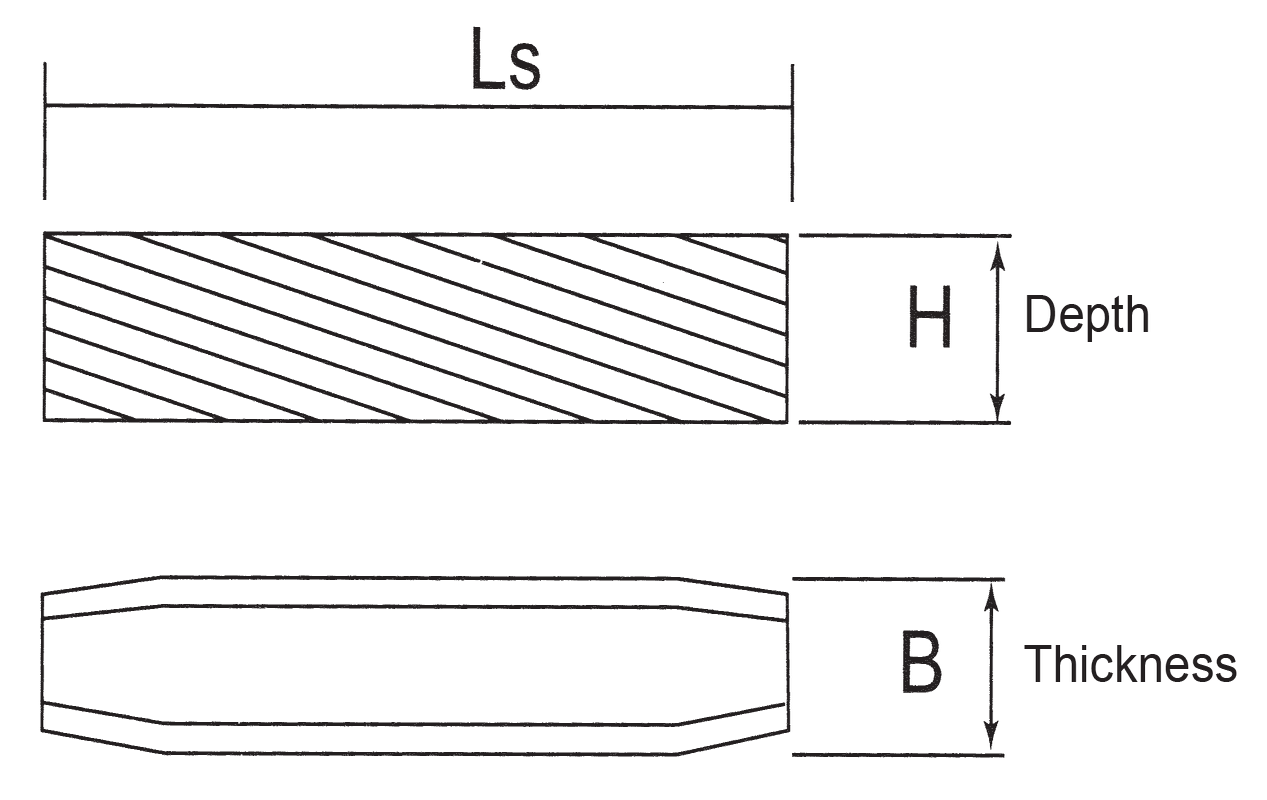

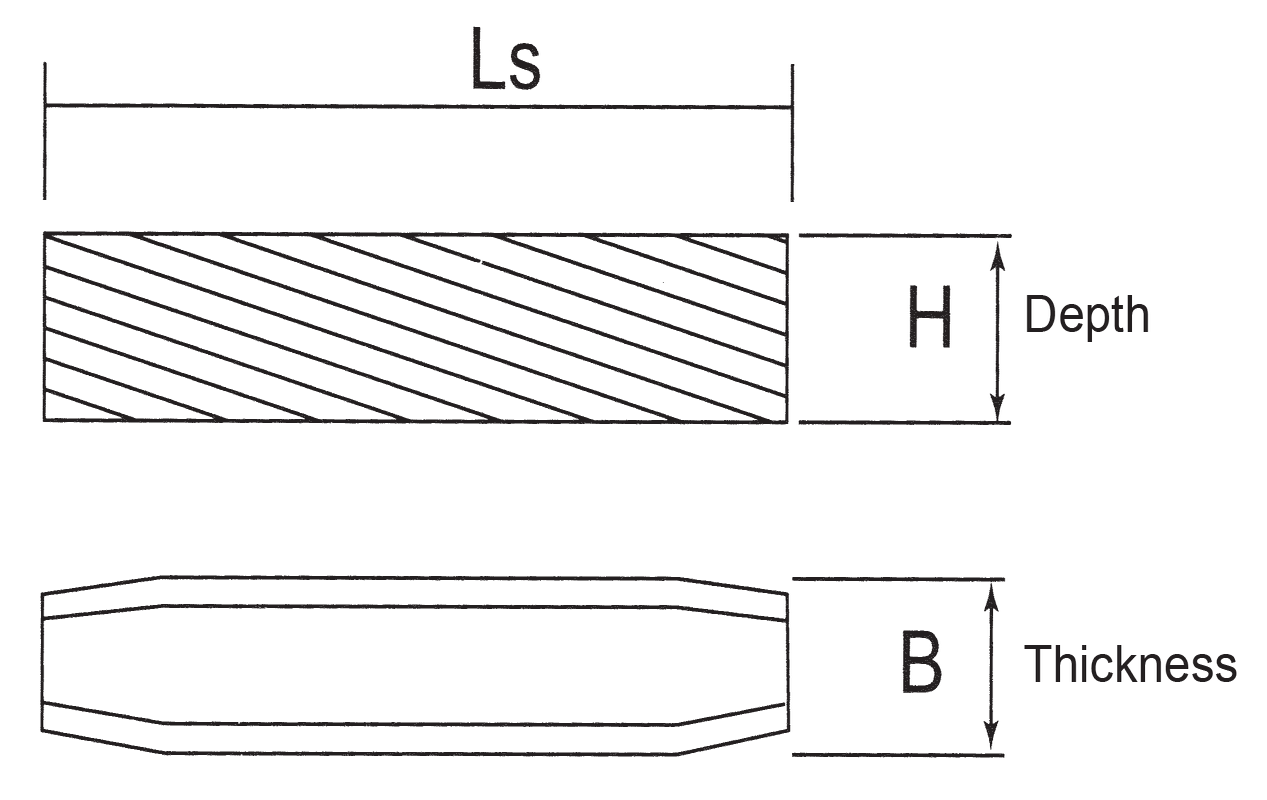

Moving Die

Stationary Die

The frequent types of thread rolling machine

| Type | Length | Thickness | Depth | |

| Moving Die (Lm') | Stationary Die (Ls') | B | H | |

| 00 | 55 | 45 | 15 | As required |

| 0 | 63 | 51 | 20 | As required |

| 1/8 | 70 | 60 | 20 | As required |

| 3/16 | 90 | 75 | 25 | As required |

| 6R | 105 | 90 | 25 | As required |

| 1/4 | 115 | 103 | 25 | As required |

| 8R | 127 | 108 | 25 | As required |

| 5/16 | 140 | 127 | 25 | As required |

| 3/8 | 165 | 150 | 25 | As required |

| 1/2 | 215 | 190 | 25 | As required |

| 3/4 | 265 | 230 | 38 | As required |

| 7/8 | 310 | 280 | 48 | As required |

| 1 | 420 | 380 | 50 | As required |

| 1-1/4 | 450 | 400 | 50 | As required |

Production capability range

- Length - MAX. 950mm

- Thickness - MAX. 400mm

- Pitch diameter - MIN . 0.25mm

How to order Thread rolling flat Dies

- Machine type / Holding angle

- Dimensions of the dies

- Thread size of bolt

- Material and hardness of workpiece

- Other special conditions

Why did you have to choose to using thread rolling flat dies?

Because of the following importance reason

- Reduced threading costs per piece

- Installation is made easy

- Reduced setup time, minimized shimming, elimination of drunkenness and extended die life due to squareness of roll-on and roll-off

- Produce a better, smoother thread with Taiwan Metiz Alliance dies

- Increased fatigue resistance due to radiused runout offered by our tools